I use the JPC-12 antenna as a portable antenna. The JPC-12 is essentially a center loaded vertical antenna, that can be used from (slash designed for) the 20 to 40 meter bands (or higher bands, see below). The band of choice is selected by adjusting the inductance of the loading coil. This loading coil can be adjusted by moving a slider, tapping the right inductance for a particular band/frequency.

Higher bands (above 20 meter)

By the way: by leaving the coil out, the antenna is also suitable for the higher bands. Adjustment is then done by adjusting the length of the telescopic whip. In this blog I will not focus on the higher bands though, my focus is on adding an extra band: the 80 meter band.

Adding the 80 meter band to the JPC-12 antenna

So I want to use the JPC-12 also on the 80 meter band. How to do this? By enlarging the inductance of the loading coil arrangement. And by adding an extra (longer) counterpoise wire.

This is how I did it:

The design I had in mind was to use both an extra loading coil ánd the original JPC-12 loading coil together (so in series). The basic idea behind this idea is that the extra loading coil (and extra counterpoise) should bring resonance for the 80 meter band itself. And the JPC-12 loading coil then should be able to tune the antenna within the 80 meter band.

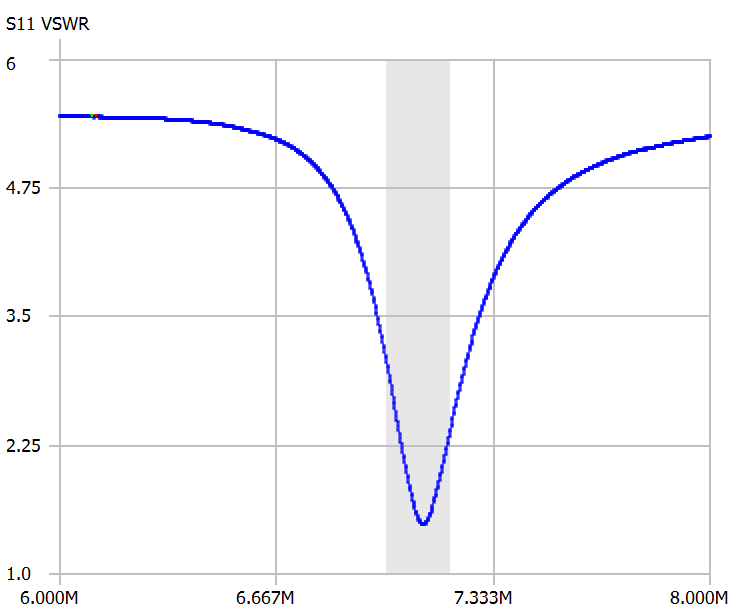

The necessity for in band tuning is because the JPC-12 vertical element is only 4,1 meter (about 13.5 ft) ‘tall’ and therefore has a very narrow bandwidth when tuned to 80 meter. Due to this narrow bandwidth only a portion of the 80 band can be used without retuning.

Now 4,1 meter is adequate for the 20 meter band. And it is OK-ish for 30 meter band. For the 40 meter band it is definitely a compromise. For the 80 meter band a 4,1 meter vertical is … well.. extremely short. A quarter wave length on 80 meter is 20 meter, so the JPC on 80 meter has only one fifth of the desired optimal length! But it’s 4,1 meter is better than nothing!

So, as a consequence of the shortness on 80 meter a very narrow bandwidth should be expected. Way less than the total bandwidth of the 80 meter band. To be able to use this antenna in any meaningfull way some kind of in band tuning is necessary. There the original JPC-12 loading coil comes in, as it can be adjusted to fine tune in band. So far my tinkering. Next question: is this feasable?

I took my VNA, my soldering iron, winding wire and started winding the extra loading coil. I also made an extra counterpoise and added to the other counterpoises.

After experimenting with different setups I found this setupworks works perfectly:

- first: add an extra counterpoise wire with a length of 20 meter;

- then: add the DIY coil and give it just enough inductance to get the JPC-12 on the lowest part of the 80 meter band. This with the JPC-coil in the position that gives the highest inductance.

- the best place for the 80m coil is between the lower sections (the black rods) and the original tuning coil of the JPC-12;

- now you can tune the JPC-12 anywhere on the 80 meter band, just by adjusting the original JPC-12 loading coil!

This is how I made the 80 meter loading coil:

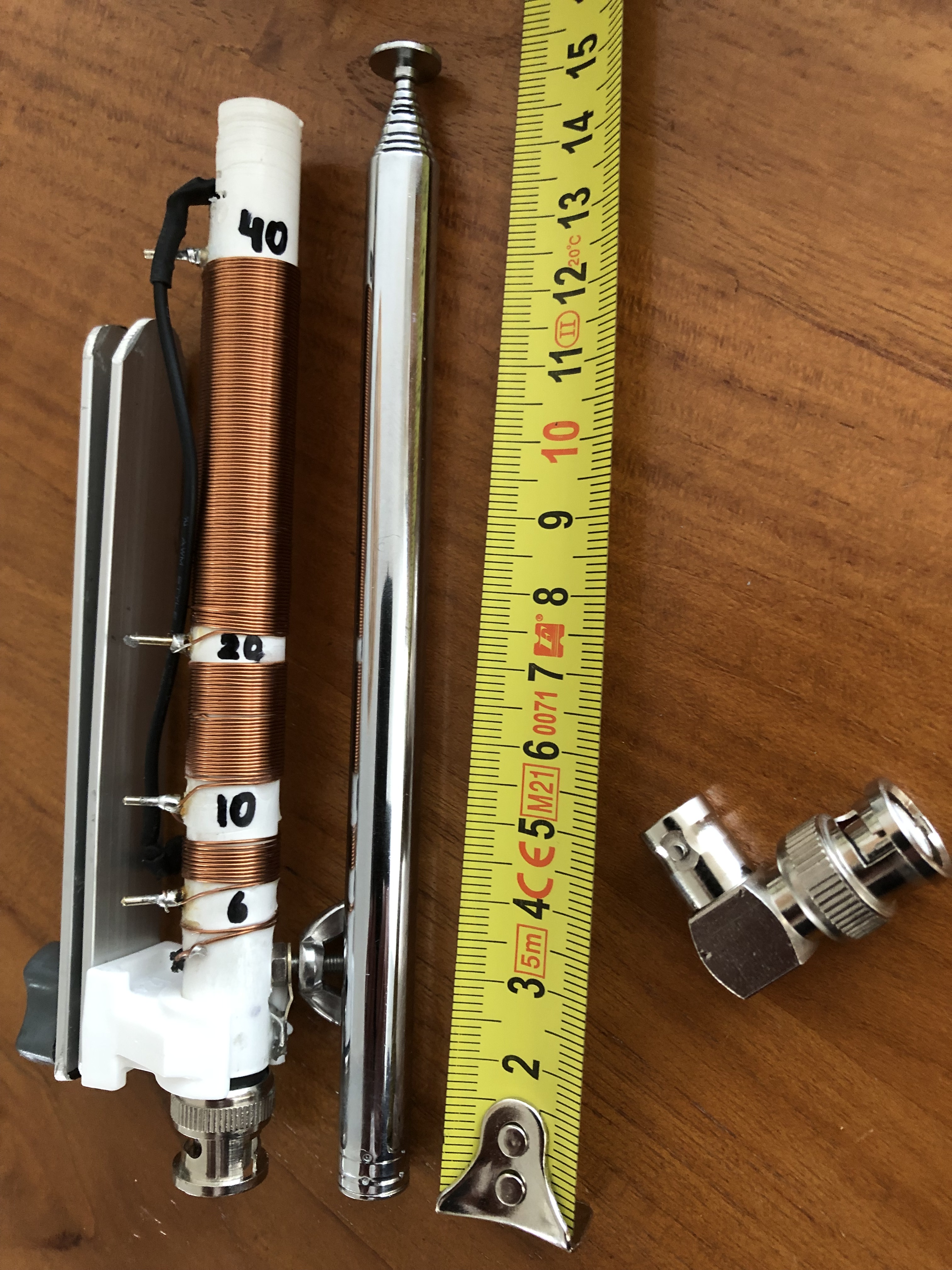

Mechanicaly: The JPC-12 uses M10 fittings to connect the different parts together. Male and female. I needed something like that to connect my DIY 80 meter loading coil into the antenna (between the black rods and the JPC inductor). As a form for the windings and the M10 fittings I used a discarded plastic vitamine container. To make the connecting parts I used two big M10 (10 mm inner diameter) and 4 cm outer diameter thumb-screws. And a M10 bolt to create the male part. The first thumb screw (the ‘female’) was placed at the lid, secured with three M3 screws and with a soldering eye fitted for the electrical connection. At the bottom of the container I created a ‘male fitting’ by drilling a 10mm whole in the bottom of the plastic container, put the M10 bolt through the hole from the inside out and fixed this bolt by screwing the thumbscrew on from the outside. A bare wire was clamped inbetween. Now I was able be to fit my ‘vitamin container loading coil’ between the black rod and the original JPC-12 loading coil. Ready for measuring…

For the loading coil itself: I wound it on the outside of the vitamin container and electrically connected it to the ends of the top and bottom fittings. See the picture to get an idea how this looks like. I picture tells more than words 😉

The 80 meter coil itself has the following dimensions:

The container is 45 mm (1.77 inch) in diameter, with 33 windings close together. I used 0,6 mm (19 AWG) enamelled copper wire. With this coil (together the original JPC-tuning coil for in band tuning) I can adjust for any frequency within the entire (regio 1) 80 meter band!

After measuring -and double checking- I protected the coil I by covering it with black plastic wrap foil. The picture below is of the container still without the foil: you can see the bare loading coil.

Some further thoughts on the design

As you can see, the plastic container I used is a bit big for the coil. Also this container is not the most sturdy thing. So a more compact and sturdier design is certainly possible!

Also: I used 0,6 mm enamel wire. Thicker wire, say 1 mm, will be better (higher Q, lower losses and able to withstand more power). But 0,6 mm is what I had lying around (like the vitamin container .. ) and I will only be using QRP power anyway. So for now this is good enough for me. I plan on a better ‘MKII ‘version, though 😉

A last remark on the enamel wire. Beware that heavier wire (and the same 33 windings) also means that the coil width is changed, and hence the inductance will be different! Keep this in mind (use a VNA to check the result)!

Now back to the results of my little project:

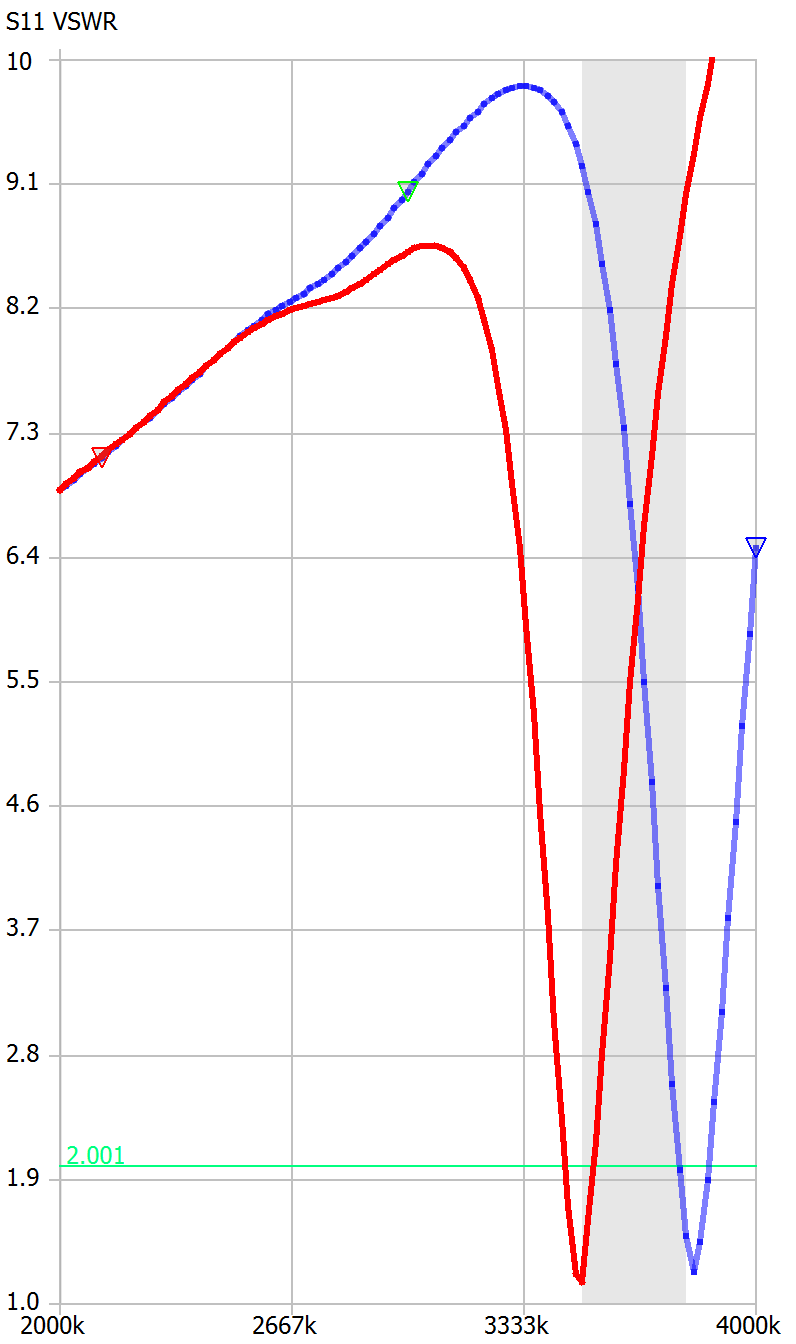

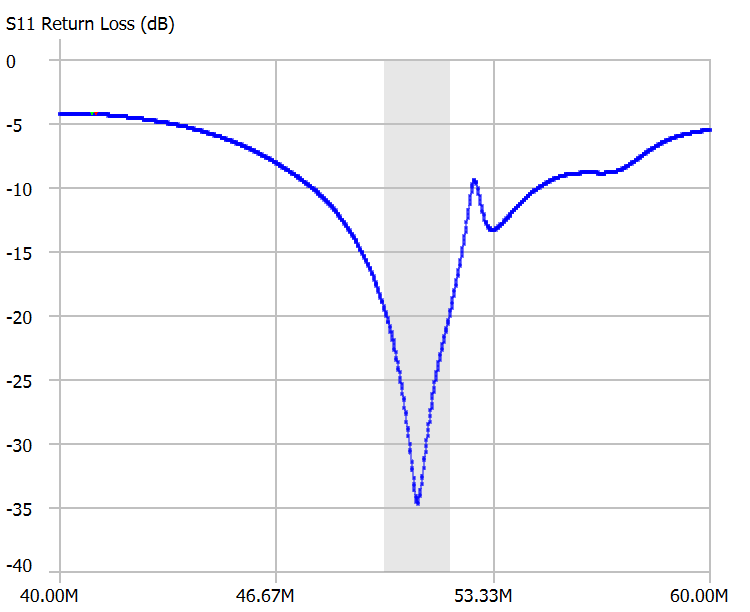

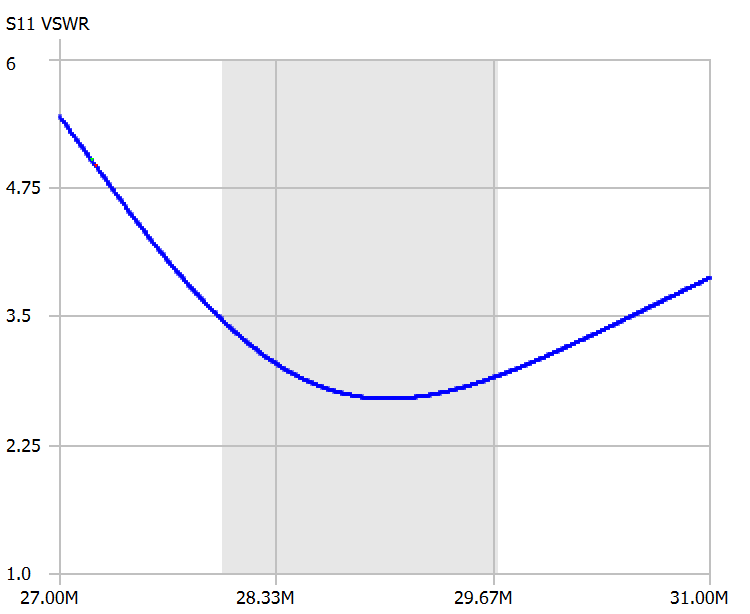

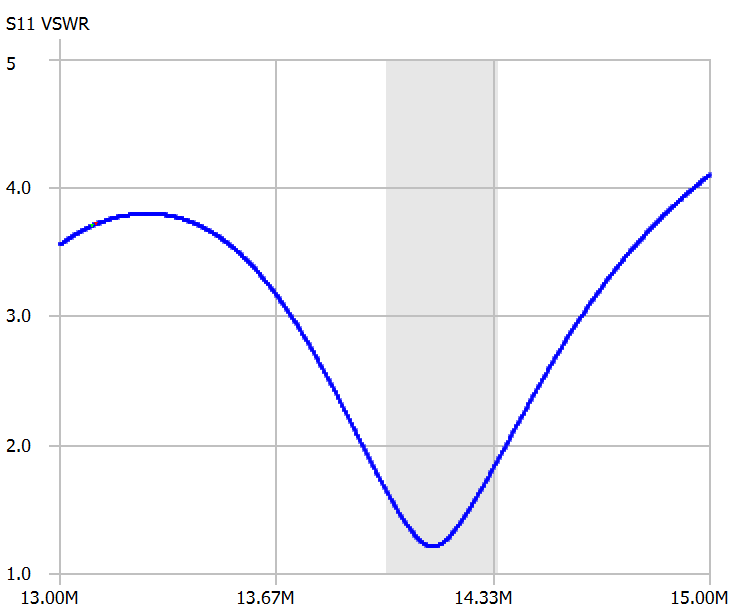

I’m happy for now: in the figure below you can see the measurements I made with my vector analyzer. Nota Bene: the grey area represents the entire regio 1 80 meter band.

The red curve corresponds with the slider of the JPC-12 loading coil in the lowest position (i.e. exactly at the low red mark on the JPC loading coil). The blue curve with the slider of the loading coil in the highest position (i.e. exactly at the high red mark on the JPC loading coil)!

I.M.H.O. this is perfect!